About Us

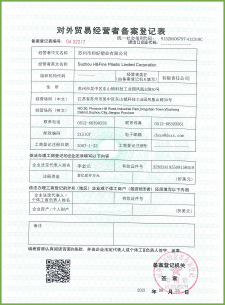

Suzhou H&Fine Eco-Tech Solutions Co.,Ltd(H&Fine Eco for short),former named Dongshan Plastics,corporate headquarter is located at Dongshan Town,Suzhou,has been engaged in food container,film printing and food packages since its establishment in 1991.Its registered capital is RMB 128 million,with a total investment of more than RMB 500 million,covers an area of about 140000 square metres and has more than 700 employees.H&Fine has advanced production facilities introduced from Japan,with annual output of 40000 tons of packing containers and 4000 tons of food package and film products.

H&Fine adheres to“Run a good business,rather than one that looks good” over the years.In food packingindustry which closely linked with food safety, H&Fine sticks to safe,clean and environmentally friendly raw mate-rials. Through clean,efficient production technology, strict production control, the implementation of strict stateinspection and testing standards,we provide high-quality packaging products at competitive price to manywell-known food manufactories.

With accumulation of technology, process, design,production management, and industrial facilities fornearly two decades, H&Fine summarized many soundand comprehensive packaging solutions, thus, we areable to provide all-in-one packaging services fromdesign to production for the special requirements ofdifferent customers within a short time,and continu-ous innovation from the material, process, appear-ance to actively assist our customers' end-productsstanding out in fierce market competition.

-

Main business

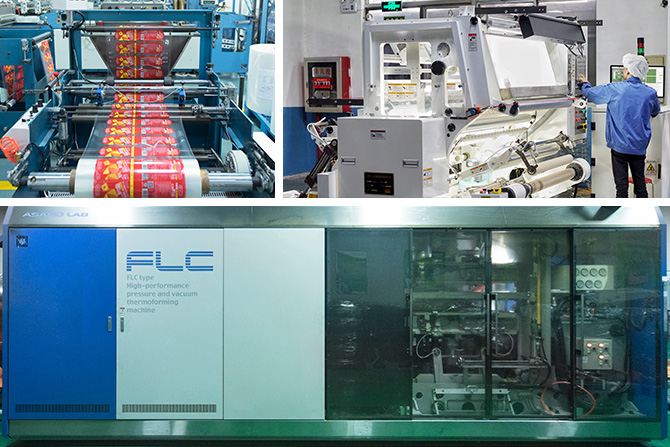

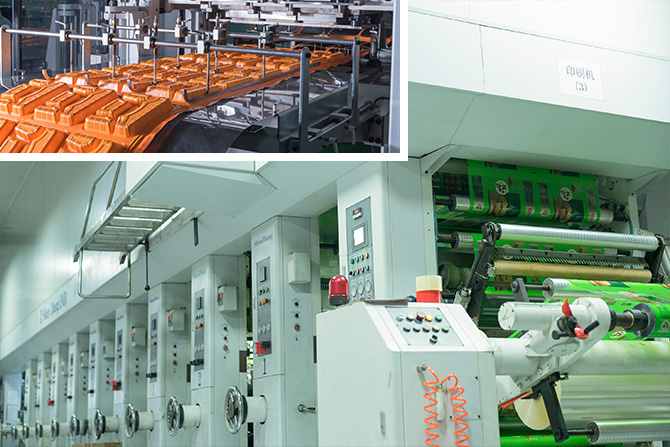

Main businessFood packaging box: H&Fine Eco has 12 sets of advanced assembly line equipment imported from Japan, and 38 sets of Automatic Blister molding equipment, with an annual production capacity of 50000 tons of food packaging container products.

Food packaging film: H&Fine Eco has 3 sets of nine color printing equipment, as well as a number of dry laminating and solvent-free laminating machines. All products must be inspected by the quality inspection machine before packaging and shipping.

-

Production technology

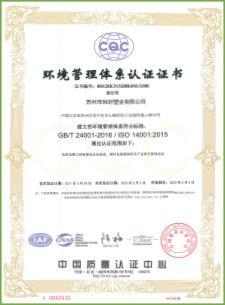

Production technologyThe product is made of food grade PP material, melted at 150 ℃ - 220 ℃ and vacuum blistered. The company's internal production management strictly in accordance with the national ISO9001 quality management system process, the whole process control.

-

Quality assurance

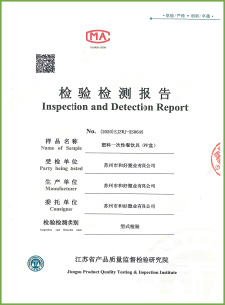

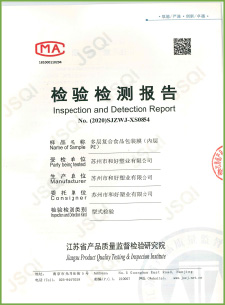

Quality assuranceThe company's production workshop is made in a dust-free space, and there is a laboratory inside. All products can be produced in batch only after the experiments of cooking, freezing, decolorization and tension. The company submits samples to the provincial official inspection agency every year to make more authoritative inspection and testing reports to ensure the quality of products.

-

Storage environment

Storage environmentThe warehouse environment of the company is clean, clean, hygienic and moisture-proof, providing a safe and clean environment for the inventory products.